How Media Blasting Works and Its Benefits

Do you have a large and difficult cleaning job, such as restoring and refurbishing various big objects and structures, removing graffiti or complicated stains, eliminating mold from hard surfaces, or cleaning machinery, equipment, and industrial parts? Then media blasting may be your best tool.

Media blasting is a process that uses high-pressure air to propel small particles against a surface. The particles dislodge dirt, grease, rust, paint, and other contaminants, leaving the surface clean and ready for refinishing. Media blasting is a versatile process that can be used on a variety of materials, including metal, wood, concrete, and plastic.

There are many benefits to using media blasting for cleaning and surface preparation. One of the biggest advantages is that it’s very effective. Media blasting can remove even the most stubborn contaminants, including rust and paint that has been baked on for years. Another benefit of media blasting is that it’s relatively quick and easy to do. A trained technician can typically blast a large surface in a matter of hours.

Media blasting can be a very safe process. The high-pressure air used in media blasting is often contained within a blast cabinet, which prevents the particles from escaping and harming the operator. Additionally, the particles used in media blasting are typically non-toxic and non-hazardous, which makes them safe to use in a variety of settings.

Overall, media blasting is a very effective and safe process for cleaning and surface preparation. It’s a versatile process that can be used on a variety of materials, and it’s relatively quick and easy to do. If you are looking for a way to clean and prepare a surface for refinishing, media blasting is a great option.

Here are some additional details about the benefits of media blasting:

- Improves adhesion: Media blasting removes contaminants from the surface, leaving it clean and free of debris. This improves the adhesion of new coatings, such as paint or powder coating.

- Increases durability: By removing contaminants, media blasting creates a more uniform surface that is less likely to corrode or rust.

- Extends the life of the surface: Media blasting can extend the life of the surface by preventing the buildup of contaminants. This can save money in the long run by reducing the need for frequent repairs or replacements.

Professional restoration companies like Colorado’s Cyclone Kleen Up often have the expertise and experience to select the most suitable media blasting solution for specific applications that will not cause damage to the surface. They consider factors such as the type of surface, the condition of the material, the desired outcome, and the type of coating or liner that will be applied. Different abrasive media, such as sand, glass beads, aluminum oxide, or walnut shells, can be used depending on the surface and the level of abrasiveness required. They understand the importance of surface preparation in achieving long-lasting and high-performance bonding for coatings and liners.

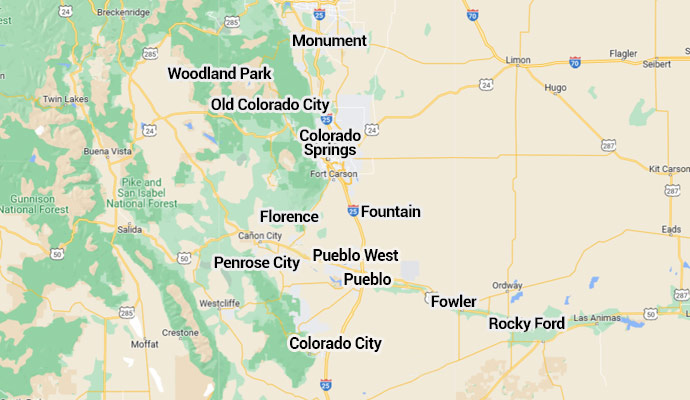

Cyclone Kleen Up has extensive experience choosing the appropriate media blasting solution for your unique application. We handle all jobs, big or small! Our media blasting services are available in Colorado Springs, Florence, Penrose, Salida, and other cities in our service area. Call 719-299-3887 or click here to make a service appointment ASAP.